Knife steel

Choose the best steel for your knife project

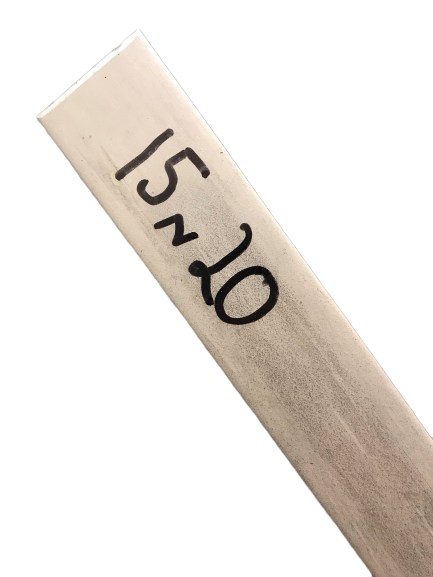

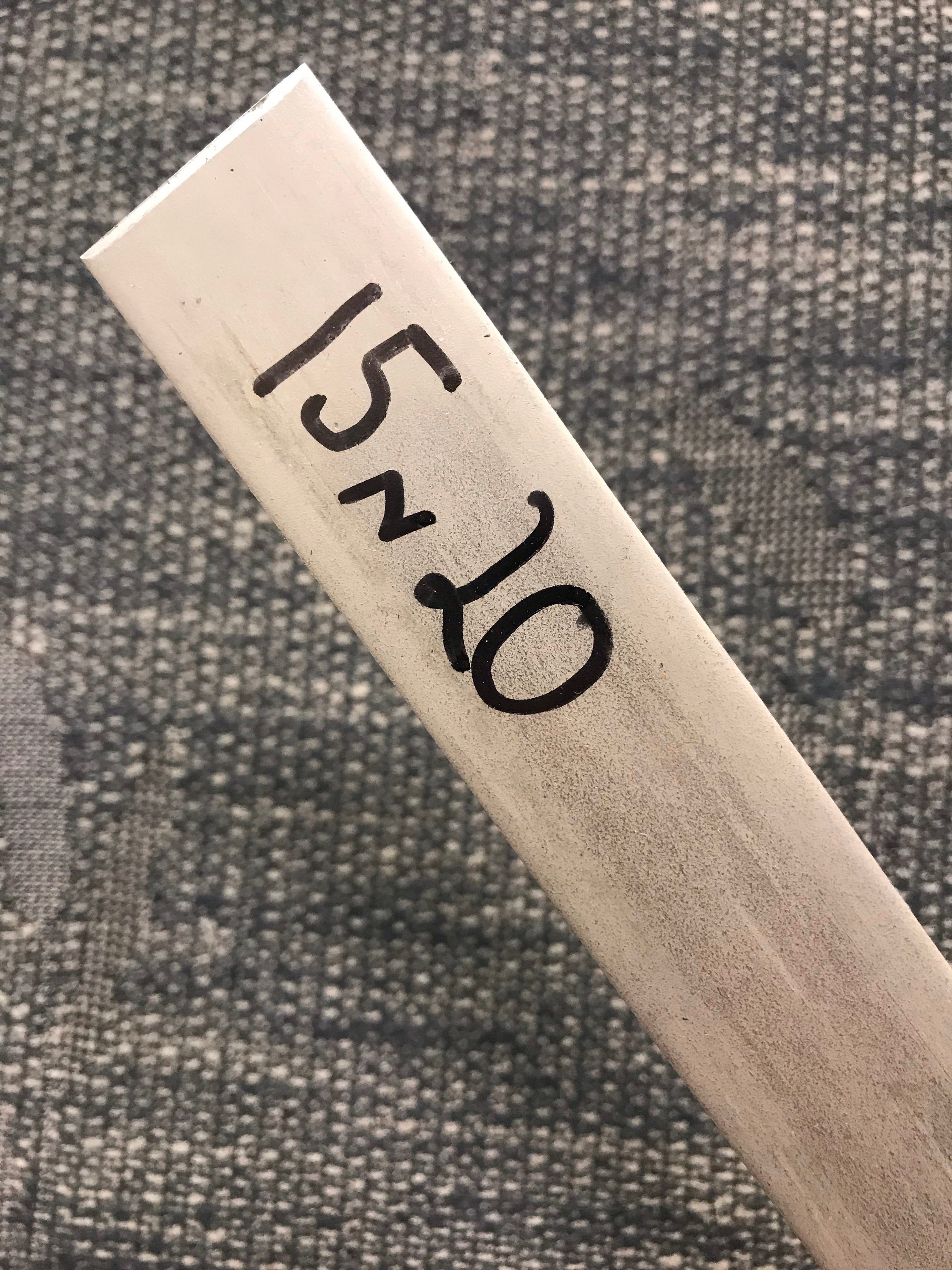

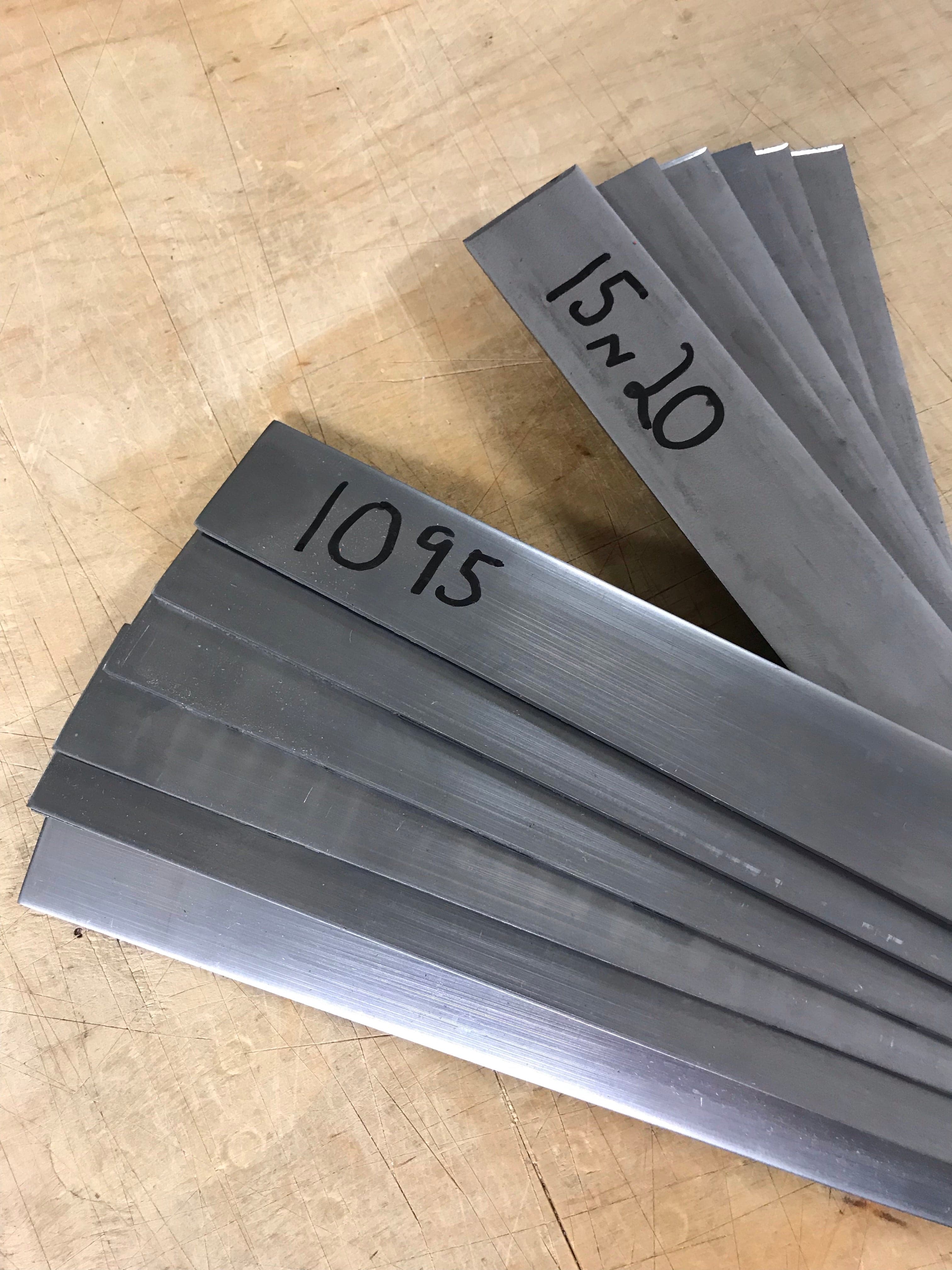

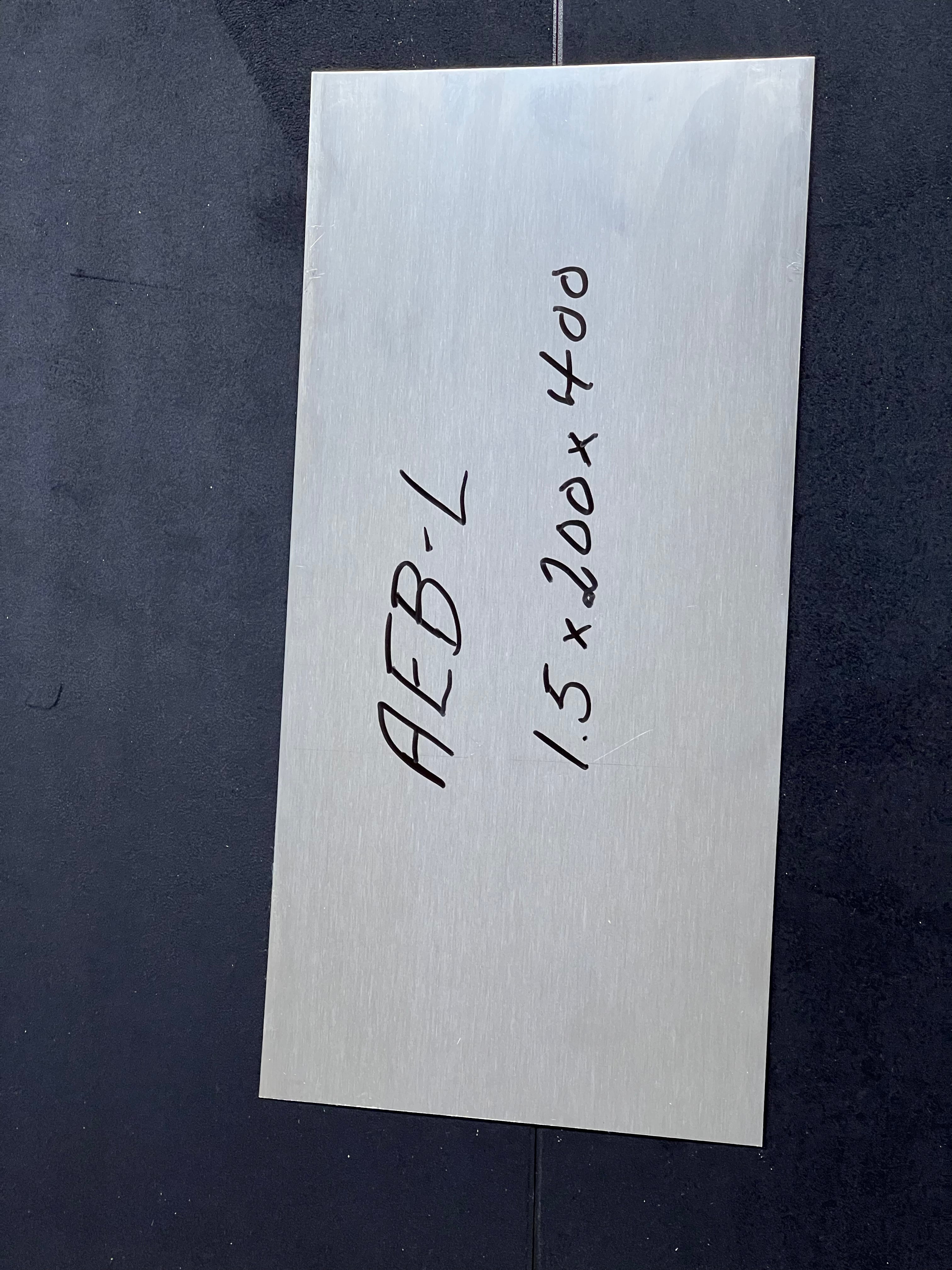

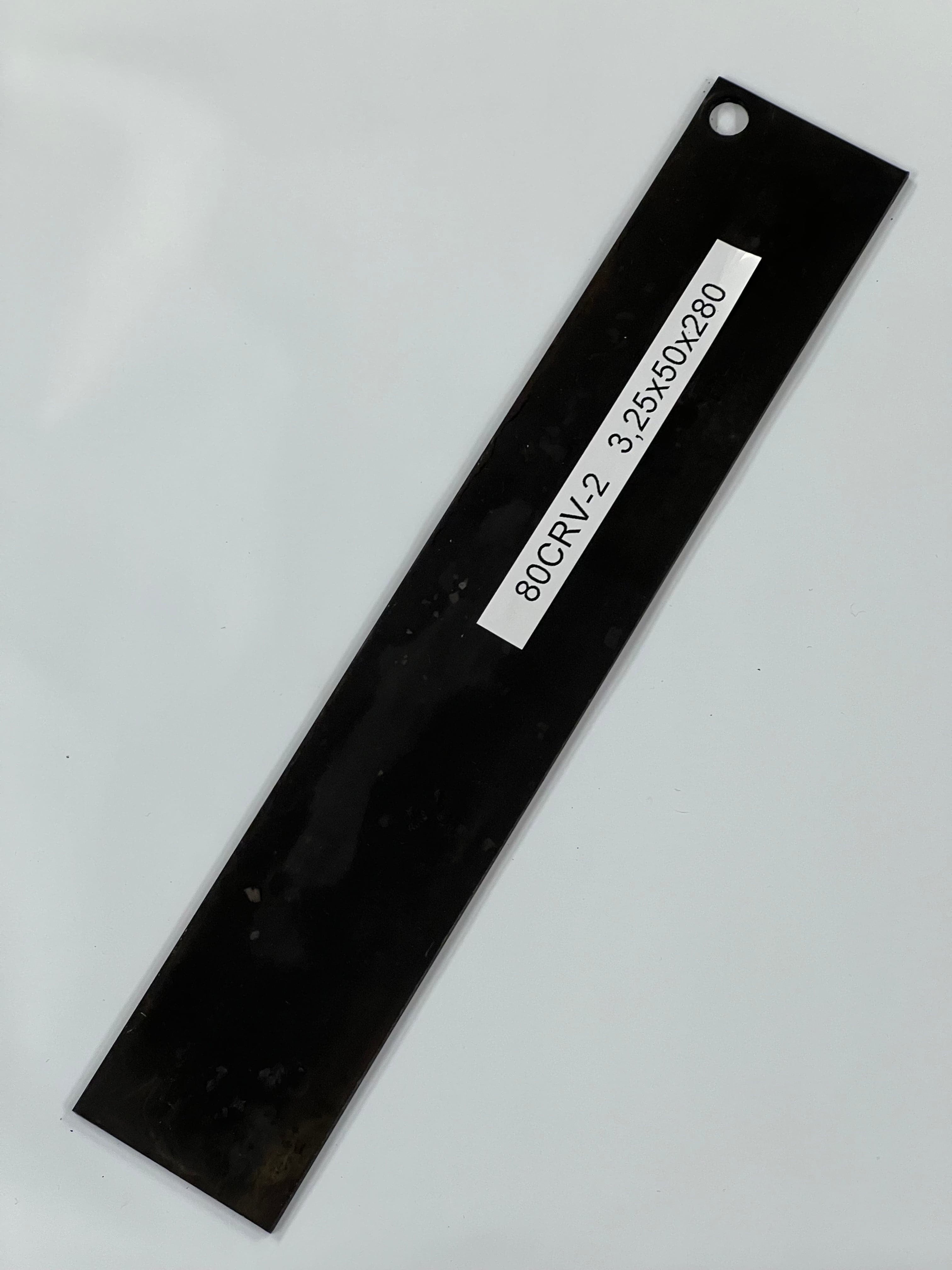

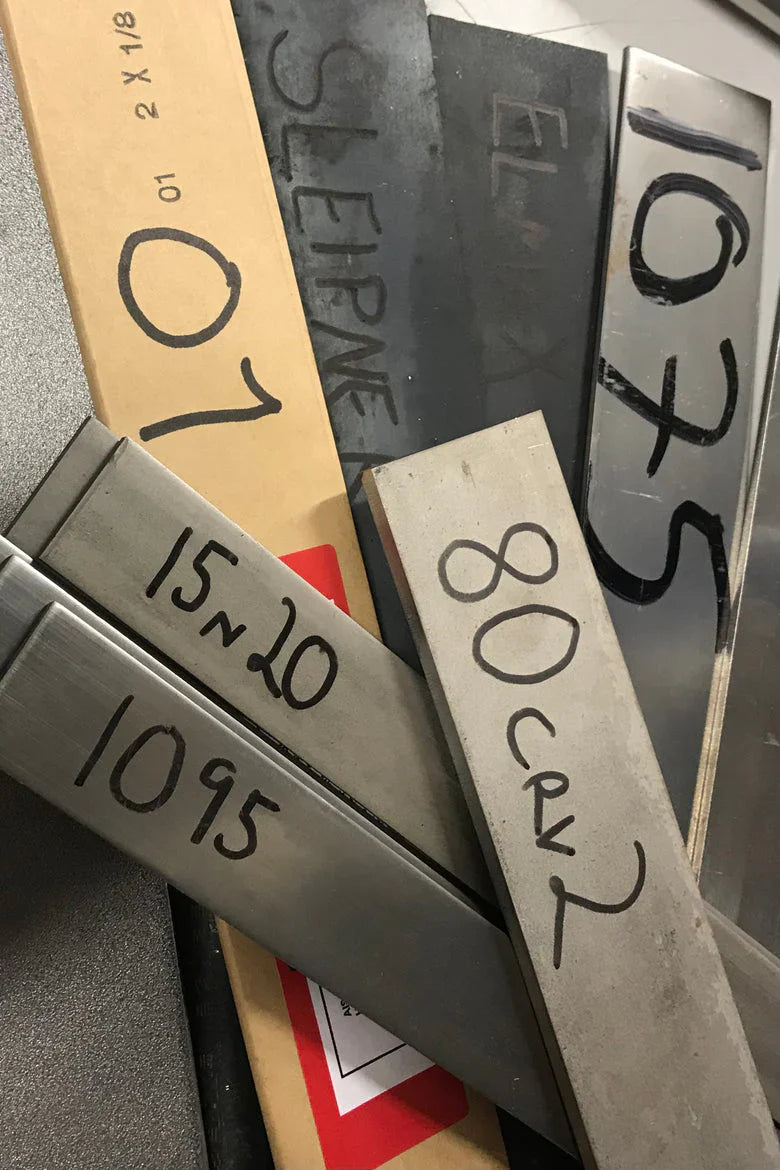

Here you will find our complete range of knife steels, a carefully selected range of high-quality steels for making knives, perfect for anyone who wants to make their own knives by grinding them from a plate or if you want to forge. We even have steel that is pre-hardened . Knife steel is absolutely crucial to the performance of any knife, but remember that a well-designed knife in a very basic knife steel like 1095 is better than a perfectly well-made knife in an expensive and advanced super steel like Elmax. Not sure what to choose? Contact us or read our guide to knife steels .

Filters

17 products

Our selection of the world's best knife steels

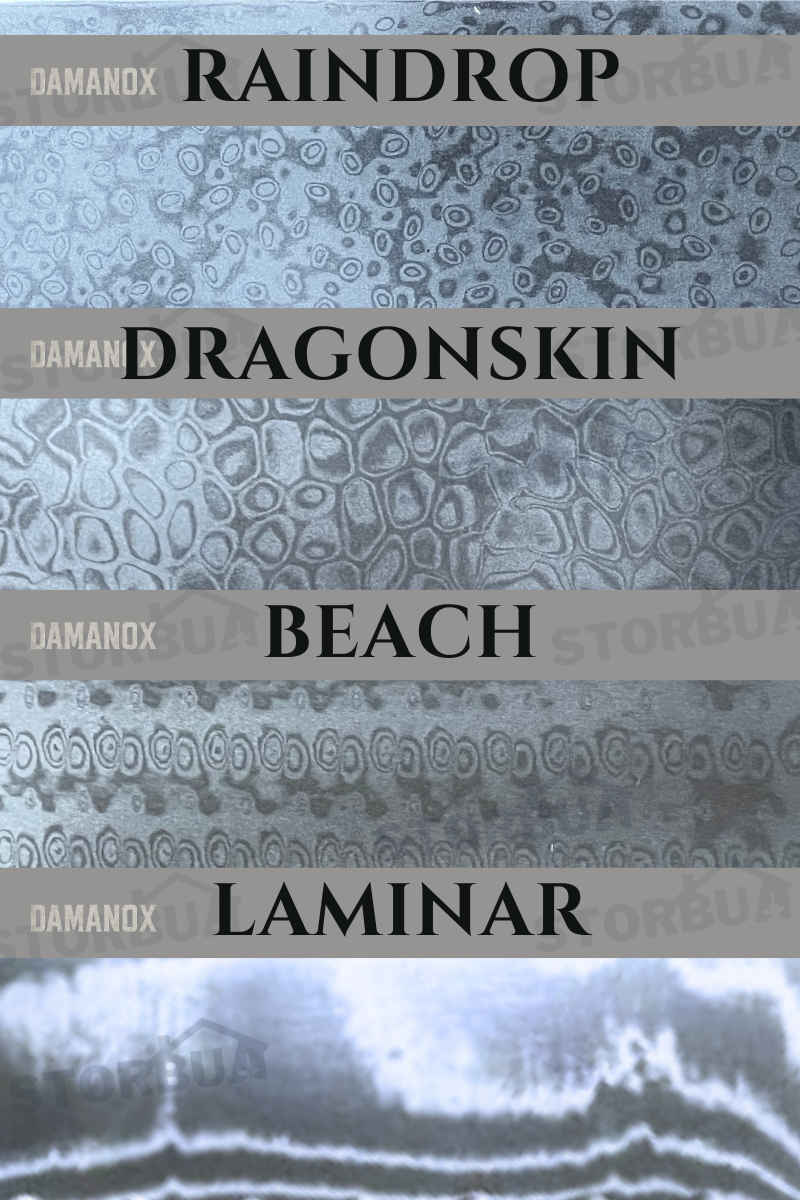

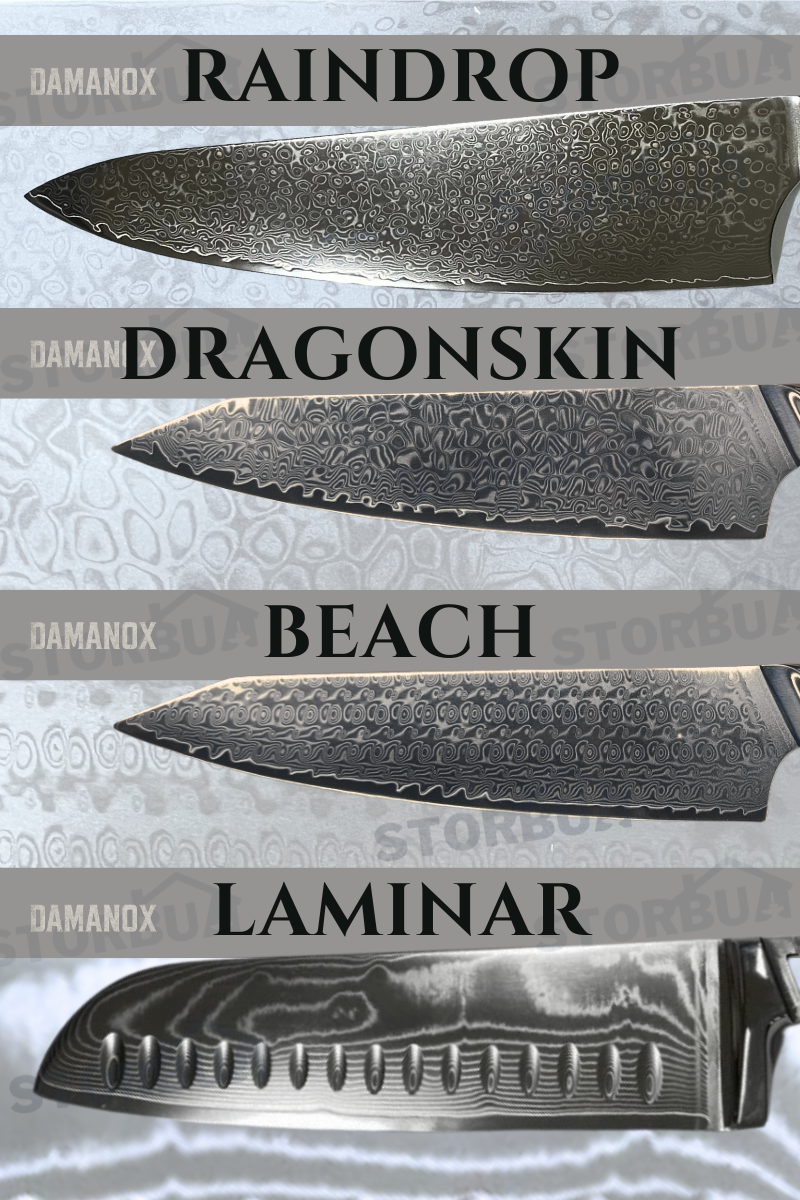

We offer only the best types of knife steel on the market, known for their hardness, durability and ability to hold a sharp edge over time. Explore our range of knife steels and find the perfect steel for your next project. Our steels includecarbon steel,stainless steeland other advanced alloys that allow you to create knives for any application with the desired balance of properties.

Choose the best quality of knife steel

Choosing a knife steel depends on the application and how you want the knife to perform. Learn more and find out which knife steels you should choose in ourGuide to knife steel, but in short, there are 3 points you need to understand in order to choose your perfect high-quality knife steel:

Hardness:The harder the steel, the finer and sharper the edge you can have and a hard edge is also more durable. So hardness gives sharpness and longer life. However, it is not that easy, and hardness is often overrated because high hardness gives a risk of the blade or edge breaking. That is why you also need toughness.

Toughness:The toughness of the steel gives the knife and its edge the ability to withstand stress. This means that a tough knife will be able to bend slightly and then spring back like a spring, rather than breaking like a hard knife. Toughness is often underestimated and is important for all knives, but is especially important in knives that will do tough jobs like nailing wood or withstand impacts and rough use.

Rust-free:Corrosion resistance is the ability of steel to resist rust. It is a sure winner for most when knives are to be used in the kitchen or at sea. However, it is not without its negative sides, as stainless steel is much more equipment-intensive to harden, while it can be more challenging to sharpen and keep sharp.

There is a tradeoff between these three, and if you want to learn more about which knife steels you should choose and why, I recommend taking a look at ourguide to knife steel.

Needs, experience and budget

When choosing a knife steel, it is important to consider your needs, experience, and budget. If you are an experienced knifemaker, you can experiment with different steels and achieve specialized properties. Beginners may benefit from starting with more user-friendly steels such as80crv2, which is easy to shape, harden and get a good result with. Or start with asteel that is already hardened.

Here are some factors to consider when choosing steel:

Application:If you are making a hunting knife, you will probably prioritize hardness and rust resistance. For kitchen knives, sharpness and the ability to hold an edge are more important to some, but others will always demand stainless.

Maintenance:Maintenance is primarily about two things. Preventing rust and keeping the edge sharp. Carbon steel achieves and maintains a very sharp edge, but requires attention to avoid rust by avoiding leaving the knife damp after use, and should be oiled at regular intervals or when stored until a natural protective layer (patina) is achieved. Stainless steel is easier to prevent rust on, and is a little harder to harden, but is often a little harder to sharpen and keep sharp.

Budget:Higher quality steel may be an investment, but the result is a knife that may perform better and will likely be even more appreciated by those who will use it, if they appreciate high quality steel. But don't worry: If you're on a tight budget, none of these steels here offer anything but stellar performance, it's just at a lower cost and perhaps a slightly less fancy name.

Whatever your requirements for knife steel, you will find the best selection at Storbua. We help you find the right steel for your project, so you can create a knife that combines quality, functionality and design.

For inspiration and tips from other knife makers, visit ourStorbuablogor follow us onInstagramandFacebookHave you made anything with our products?Send us picturesand show off what you make! Join the community!