Silicone for mold casting AS40

Tax included.

Det er risikofritt å handle hos oss

Tusenvis av fornøyde kunder

Rask levering

(1-3 dager)

Kjøp nå,

betal senere

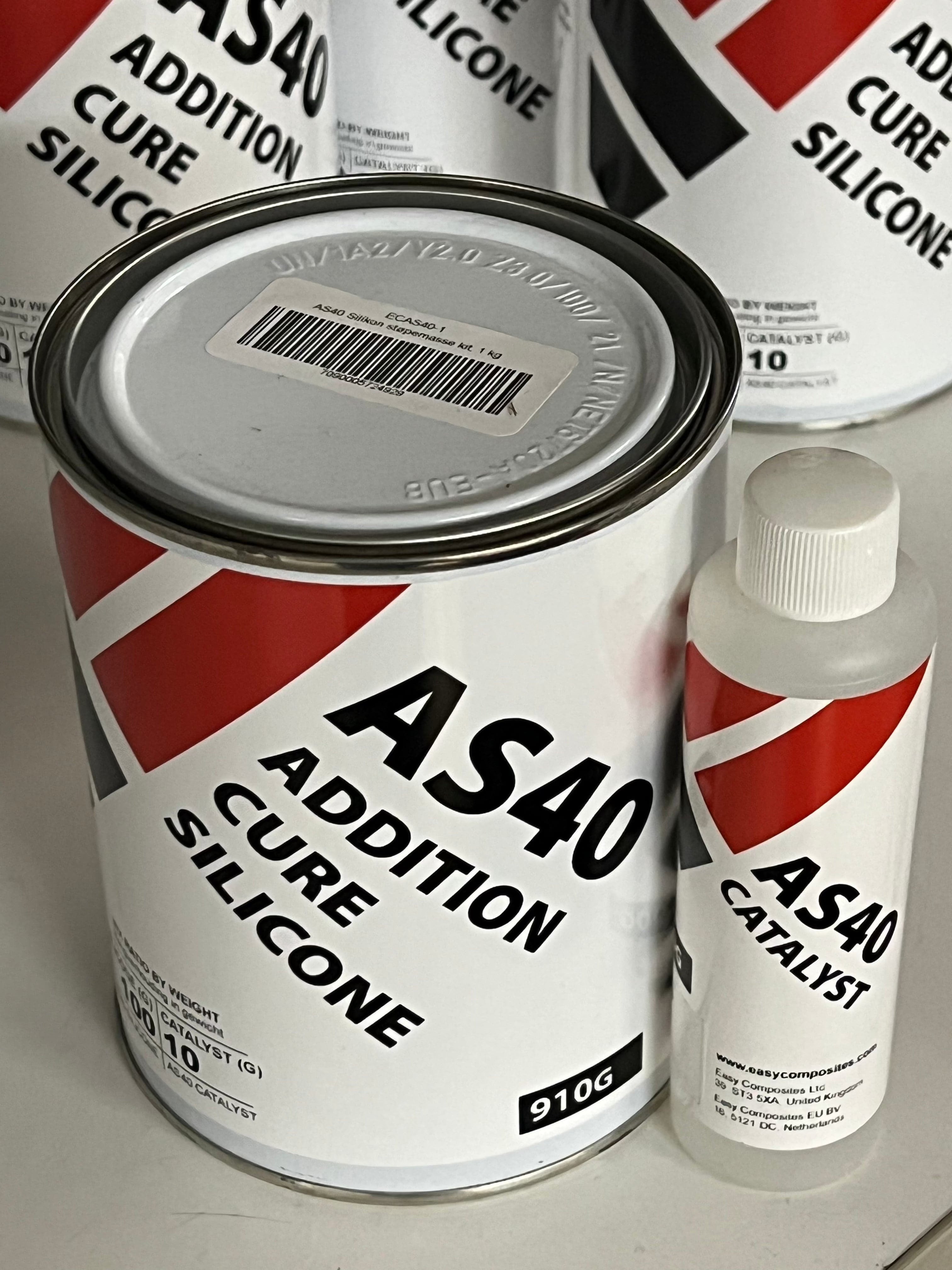

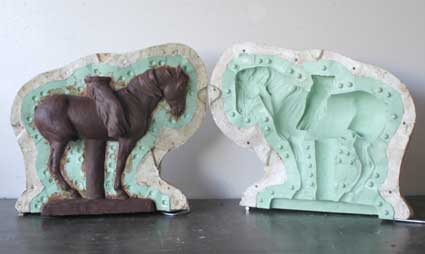

AS40 Silicone Rubber is a 2-component casting compound used to make casts of other objects. This compound provides a very accurate cast/reproduction of the object being cast.

Great durability

Cured AS40 Silicone Rubber is highly durable, has low shrinkage, has high tear strength and can often be used for many castings. It is resistant to styrene.

Transparent and can be colored

The silicone has a nice transparency, can be cast completely clear or can be colored with our epoxy colors . The example pictures are with added color or just examples of what can be made.

Mixing ratios and curing times

100 parts by weight base (Addition Cure Silicone Rubber)

10 parts by weight hardener (Catalyst)

Density: 1.08 grams/cm3 at 20 degrees

Pot life after base and hardener are mixed together: Approx. 30 minutes at 20°C

Curing time at 20°C: Approximately 24 hours.

Curing time at 60°C: Approximately 2 hours.

Curing time at 70°C: Approximately 1 hour.

Curing time at 80°C: Approx. 30 minutes

The casting compound hardens down to 10°C, but the hardening time is longer at low temperatures.

This casting compound consists of two components (base and hardener), and the package comes with the correct amount of each component. The base and hardener must be mixed together in the correct ratio for the casting compound to harden.

Instructions for use

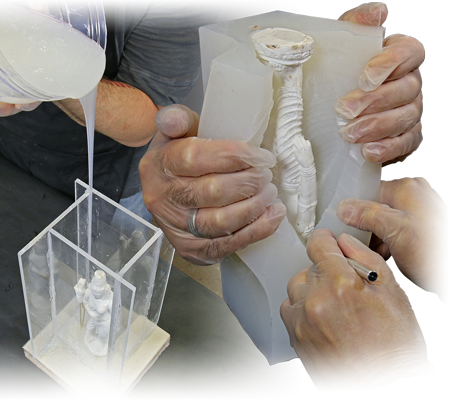

- Find an empty box or crate to use for the casting work.

- Place the object to be cast/reproduced in the box. It is best to glue it to the bottom of the box so that it does not move when you pour in the casting compound.

- Shake the bottle of hardener before mixing it with the base.

- Use a mixing cup, a measuring syringe or a scale to measure out the correct amount of base and hardener.

- Mix well, but carefully to avoid "whipping" air into the mixture when mixing the two components.

- Scrape the edges and bottom of the mixing cup to ensure that you mix the hardener and base well together.

- Then pour the ready-mixed casting compound over the object in the box that is to be cast. Pour carefully and in a thin stream. Let the casting compound flow over and cover the object in the box.

- If air bubbles appear on the surface of the casting compound, you can puncture them with a toothpick. If you have a vacuum chamber, this can also be used to remove air bubbles from the casting compound.

- Let the casting compound cure for 24 hours at 20°C. If you increase the temperature, the curing process will go faster.

- Once the casting compound has hardened, detach the crate or box from the hardened casting compound.

- Then loosen the casting compound from the object you have made a cast of. If necessary, use a wallpaper knife to help.

- If you have used a tape knife to split the hardened casting compound to release it from the object you have cast, you can then tape the mold back together before filling it with epoxy to make a new reproduction.

Thickener

Mix 1-3% thickener into the silicone to make the silicone thicker to be able to apply the silicone to sculptures and vertical surfaces. A 50g bottle can cover up to 5kg of silicone, or slightly less if you want it to be more viscous.

Always do a test

AS40 Silicone Rubber can be used to take casts of most types of objects in plastic, metal, wood, etc. Remember, some objects must be inserted with wax before pouring the casting compound so that it will release from the object after hardening.

We always recommend that you do a test before carrying out important work so that you are confident in how the materials work.

AS40 silicone casting compound is almost odorless.

Wear gloves and protective glasses and make sure to work under the conditions indicated in the safety data sheet.

Additional technical information sheet (English)

Vi sender bortimot alle bestillinger samme virkedag hvis du bestiller før kl. 14.00.

Vanlig leveringstid: 1–3 virkedager med Bring.

Kunder i Nord-Norge kan ta en dag eller to ekstra i noen tilfeller.

Sporing:

Du mottar sporingsnummer på e-post så snart pakken er sendt.

100 % fornøydgaranti:

Vi er helt sikre på at du blir fornøyd. Vi er så sikre at vi tilbyr både full retur og dekking av returfrakt. Uansett. Det er altså helt uten risiko for deg å bestille nå for å inspisere produktet selv i eget hjem og eget tempo.

Vi lagerfører også reservedeler og slitedeler, slik at om du skulle være uheldig å ødelegge noe eller mot formodning greie å slite ut brynene så kan disse enkelt erstattes.

Enkel retur:

Kontakt oss på kundeservice, så sender vi deg en ferdig utfylt returetikett.

Ingen spørsmål – ingen risiko

Beskrivelse:

AS40 Silicone Rubber is a 2-component casting compound used to make casts of other objects. This compound provides a very accurate cast/reproduction of the object being cast.

Great durability

Cured AS40 Silicone Rubber is highly durable, has low shrinkage, has high tear strength and can often be used for many castings. It is resistant to styrene.

Transparent and can be colored

The silicone has a nice transparency, can be cast completely clear or can be colored with our epoxy colors . The example pictures are with added color or just examples of what can be made.

Mixing ratios and curing times

100 parts by weight base (Addition Cure Silicone Rubber)

10 parts by weight hardener (Catalyst)

Density: 1.08 grams/cm3 at 20 degrees

Pot life after base and hardener are mixed together: Approx. 30 minutes at 20°C

Curing time at 20°C: Approximately 24 hours.

Curing time at 60°C: Approximately 2 hours.

Curing time at 70°C: Approximately 1 hour.

Curing time at 80°C: Approx. 30 minutes

The casting compound hardens down to 10°C, but the hardening time is longer at low temperatures.

This casting compound consists of two components (base and hardener), and the package comes with the correct amount of each component. The base and hardener must be mixed together in the correct ratio for the casting compound to harden.

Instructions for use

- Find an empty box or crate to use for the casting work.

- Place the object to be cast/reproduced in the box. It is best to glue it to the bottom of the box so that it does not move when you pour in the casting compound.

- Shake the bottle of hardener before mixing it with the base.

- Use a mixing cup, a measuring syringe or a scale to measure out the correct amount of base and hardener.

- Mix well, but carefully to avoid "whipping" air into the mixture when mixing the two components.

- Scrape the edges and bottom of the mixing cup to ensure that you mix the hardener and base well together.

- Then pour the ready-mixed casting compound over the object in the box that is to be cast. Pour carefully and in a thin stream. Let the casting compound flow over and cover the object in the box.

- If air bubbles appear on the surface of the casting compound, you can puncture them with a toothpick. If you have a vacuum chamber, this can also be used to remove air bubbles from the casting compound.

- Let the casting compound cure for 24 hours at 20°C. If you increase the temperature, the curing process will go faster.

- Once the casting compound has hardened, detach the crate or box from the hardened casting compound.

- Then loosen the casting compound from the object you have made a cast of. If necessary, use a wallpaper knife to help.

- If you have used a tape knife to split the hardened casting compound to release it from the object you have cast, you can then tape the mold back together before filling it with epoxy to make a new reproduction.

Thickener

Mix 1-3% thickener into the silicone to make the silicone thicker to be able to apply the silicone to sculptures and vertical surfaces. A 50g bottle can cover up to 5kg of silicone, or slightly less if you want it to be more viscous.

Always do a test

AS40 Silicone Rubber can be used to take casts of most types of objects in plastic, metal, wood, etc. Remember, some objects must be inserted with wax before pouring the casting compound so that it will release from the object after hardening.

We always recommend that you do a test before carrying out important work so that you are confident in how the materials work.

AS40 silicone casting compound is almost odorless.

Wear gloves and protective glasses and make sure to work under the conditions indicated in the safety data sheet.

Additional technical information sheet (English)