1095 Carbon steel

Tax included.

Det er risikofritt å handle hos oss

Tusenvis av fornøyde kunder

Rask levering

(1-3 dager)

Kjøp nå,

betal senere

1095 steel is a widely used knife steel. Also called C100s, it is a carbon steel that can be used in solid steel blades, as edge steel in laminated knife blades or in damask. The steel is therefore well suited for both stock removal and forging.

By differential hardening you will be able to give the knife an unparalleled hamon, see example image!

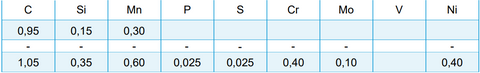

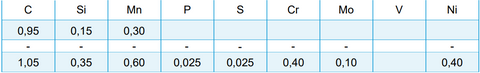

Composition:

In demand and famous worldwide, 1095 is known to most knife makers and is a steel everyone should try.

Austenitizing temperature (hardening temperature): 800-830 C

Example of curing procedure:

- Heat up to critical temperature (non-magnetic) of around 800 C.

- Cool in water, brackish water or oil. The temperature should go from 800 to below 540 in less than 5 seconds to prevent pearlite formation.

- 200C for 2 hours, then cool in air to room temperature

- 200C for another 2 hours.

We always recommend trying out the hardening process when using a new steel.

The term Sort means Sorting which indicates how flat the piece of steel is. For example, 1st sorting has a bend of less than 1mm per meter, and is therefore practically flat. If you need something flatter than 1st sorting, you must buy flat-ground steel, such as our O1 tool steel or some of our hot rolled steel. Contact us for assistance.

2nd grade has from 1mm up to 4mm bend and 3rd grade has 4mm or more. In other words, 1st grade is the flattest pieces of that type, and 3rd grade is the one with the most bend. The bend comes from the steel being stored on large rolls before being unrolled and cut into smaller pieces, some bend can also come from when the steel is cut.

Contact us if you have any questions!

Vi sender bortimot alle bestillinger samme virkedag hvis du bestiller før kl. 14.00.

Vanlig leveringstid: 1–3 virkedager med Bring.

Kunder i Nord-Norge kan ta en dag eller to ekstra i noen tilfeller.

Sporing:

Du mottar sporingsnummer på e-post så snart pakken er sendt.

100 % fornøydgaranti:

Vi er helt sikre på at du blir fornøyd. Vi er så sikre at vi tilbyr både full retur og dekking av returfrakt. Uansett. Det er altså helt uten risiko for deg å bestille nå for å inspisere produktet selv i eget hjem og eget tempo.

Vi lagerfører også reservedeler og slitedeler, slik at om du skulle være uheldig å ødelegge noe eller mot formodning greie å slite ut brynene så kan disse enkelt erstattes.

Enkel retur:

Kontakt oss på kundeservice, så sender vi deg en ferdig utfylt returetikett.

Ingen spørsmål – ingen risiko

Beskrivelse:

1095 steel is a widely used knife steel. Also called C100s, it is a carbon steel that can be used in solid steel blades, as edge steel in laminated knife blades or in damask. The steel is therefore well suited for both stock removal and forging.

By differential hardening you will be able to give the knife an unparalleled hamon, see example image!

Composition:

In demand and famous worldwide, 1095 is known to most knife makers and is a steel everyone should try.

Austenitizing temperature (hardening temperature): 800-830 C

Example of curing procedure:

- Heat up to critical temperature (non-magnetic) of around 800 C.

- Cool in water, brackish water or oil. The temperature should go from 800 to below 540 in less than 5 seconds to prevent pearlite formation.

- 200C for 2 hours, then cool in air to room temperature

- 200C for another 2 hours.

We always recommend trying out the hardening process when using a new steel.

The term Sort means Sorting which indicates how flat the piece of steel is. For example, 1st sorting has a bend of less than 1mm per meter, and is therefore practically flat. If you need something flatter than 1st sorting, you must buy flat-ground steel, such as our O1 tool steel or some of our hot rolled steel. Contact us for assistance.

2nd grade has from 1mm up to 4mm bend and 3rd grade has 4mm or more. In other words, 1st grade is the flattest pieces of that type, and 3rd grade is the one with the most bend. The bend comes from the steel being stored on large rolls before being unrolled and cut into smaller pieces, some bend can also come from when the steel is cut.

Contact us if you have any questions!